13 Years Manufacturer U-1A00 thermal wax actuator for thermostatic automatic water drain valve to Spain Manufacturer

Short Description:

Product Detail

Product Tags

13 Years Manufacturer U-1A00 thermal wax actuator for thermostatic automatic water drain valve to Spain Manufacturer Detail:

1. Operation Principle

The Thermostatic Wax that has been sealed in shell body induces expansion by a given temperature, and inner rubber seal part drives its handspike to move under expansion pressure to realize a transition from thermal energy into mechanical energy. The Thermostatic Wax brings an upward movement to its handspike, and automatic control of various function are realized by use of upward movement of handspike. The return of handspike is accomplished by negative load in a given returned temperature.

2. Characteristic

(1)Small body size, occupied limited space, and its size and structure may be designed in according to the location where needs to work.

(2)Temperature control is reliable and nicety

(3)No shaking and tranquilization in working condition.

(4)The element doesn’t need special maintenance.

(5)Working life is long.

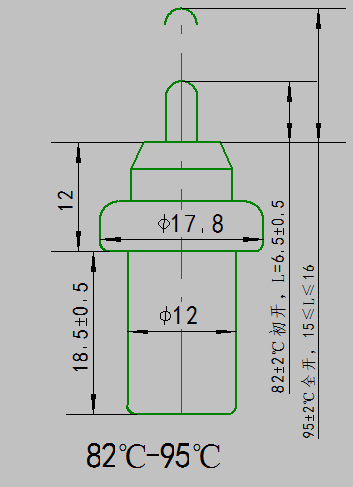

3.Main Technical Parameters

(1)Handspike’s height may be confirmed by drawing and technical parameters

(2)Handspike movement is relatives to the temperature range of the element, and the effective distance range is from 1.5mm to 20 mm.

(3)Temperature control range of thermal wax actuator is between –20 ~ 230℃.

(4)Lag phenomenon is generally 1 ~ 2℃. Friction of each component part and lag of the component part temperature cause a lag phenomenon. Because there is a difference between up and down curve of traveling distance.

(5)Loading force of thermal wax actuator is difference, it depends on its’ shell size.

Product detail pictures:

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for 13 Years Manufacturer U-1A00 thermal wax actuator for thermostatic automatic water drain valve to Spain Manufacturer, The product will supply to all over the world, such as: Macedonia , Czech Republic , United States , The president and all the company members would like to provide qualified goods and services for customers and sincerely welcome and cooperate with all native and foreign customers for a bright future.

Added coolant to cold engine. Started car, continued to add coolant to radiator until full. Turned on A/C. Checked for fan to come on, never did. Let run for about 5 minutes. No steam or moisture in tailpipes.

For a full explanation and code see:

https://www.element14.com/community/community/design-challenges/vertical-farming/blog/2016/01/08/automated-green-house-blog134–ph-control-ph-probe-lcd-readout-gui-probe-health-readout