High Quality Industrial Factory Special Wax in Agriculture and Forestry to Thailand Manufacturer

Short Description:

Product Detail

Product Tags

High Quality Industrial Factory Special Wax in Agriculture and Forestry to Thailand Manufacturer Detail:

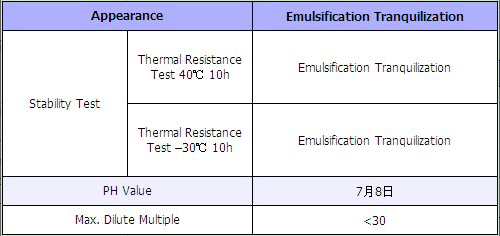

(1)YNE4 Series Special Molding Moisturized Wax for Fruit Trees

In order to protect fruit trees and shrubs from desiccation during winter dormancy or transportation or to keep moisture in summer drought, Special Molding Moisturized Wax is spayed on the surface of trees, forming the protecting film in surface of trees. The film has some adequate micro pore that could efficiently reduce the losses of moisture in the surface of the trees, and it simultaneously ensures physiological respiration of the trees.

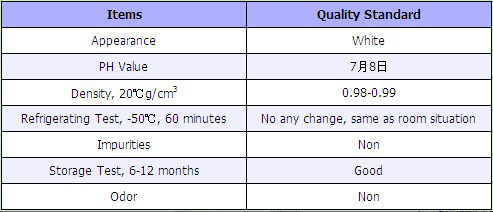

(2) YNE5 Series Special Preventing Frostbite Wax for Trees

(3) In large northern areas of our country, the winter season is severe cold and the spring season is more heavy windy.

The early winter and the late spring’s frost are quite disadvantage to young plant, the weather is particularly abnormal coldness after spring comes, and frequently injures these trees. As a result young plant is cold death. YNE5 Series Special Preventing Frostbite Wax for Trees not only has anti-freezing effect on trees but also well effect on anti-sprouting etc. Spraying on branches and leaves of trees can make exuberant growth of foliage.

Product detail pictures:

As a way to provide you advantage and enlarge our organization, we even have inspectors in QC Crew and guarantee you our greatest assistance and product or service for High Quality Industrial Factory Special Wax in Agriculture and Forestry to Thailand Manufacturer, The product will supply to all over the world, such as: Cyprus , America , Estonia , Relying on superior quality and excellent post-sales, our products sell well in America, Europe, the Middle East and South Africa. We are also the appointed OEM factory for several worlds' famous products brands. Welcome to contact us for further negotiation and cooperation.

This is part 3 of the Removal and Repair of the throttle body and idle air control valve on 1991 22re Toyota pickup. This repair was done to stop a surging idle.

Episode 7 of 9, The Future of the Internal Combustion Engine

Inside Koenigsegg provides for the first time, a look behind the scenes at Koenigsegg and examine how innovation within the highest echelon of sports car manufacturers will affect the broader automotive world. Company founder and principal, Christian Von Koenigsegg, hosts this nine-part series, which was produced at Koenigsegg headquarters in Angelholm, Sweden.

In the seventh episode, Christian Von Koenigsegg and Urban Carlson demonstrate their Free Valve technology that does not require a camshaft to run. This engineering is being pioneered by Koenigsegg for future use, but is already running in a Saab 9-5 test mule.