professional factory provide U-1A00 thermal wax actuator for thermostatic automatic water drain valve Supply to Vietnam

Short Description:

Product Detail

Product Tags

professional factory provide U-1A00 thermal wax actuator for thermostatic automatic water drain valve Supply to Vietnam Detail:

1. Operation Principle

The Thermostatic Wax that has been sealed in shell body induces expansion by a given temperature, and inner rubber seal part drives its handspike to move under expansion pressure to realize a transition from thermal energy into mechanical energy. The Thermostatic Wax brings an upward movement to its handspike, and automatic control of various function are realized by use of upward movement of handspike. The return of handspike is accomplished by negative load in a given returned temperature.

2. Characteristic

(1)Small body size, occupied limited space, and its size and structure may be designed in according to the location where needs to work.

(2)Temperature control is reliable and nicety

(3)No shaking and tranquilization in working condition.

(4)The element doesn’t need special maintenance.

(5)Working life is long.

3.Main Technical Parameters

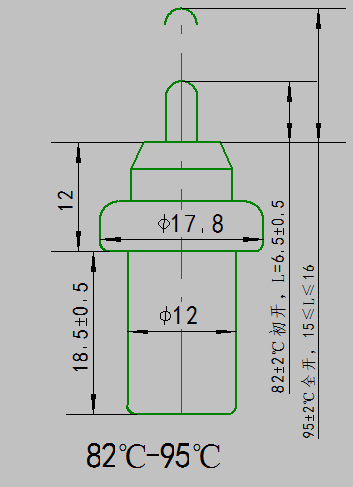

(1)Handspike’s height may be confirmed by drawing and technical parameters

(2)Handspike movement is relatives to the temperature range of the element, and the effective distance range is from 1.5mm to 20 mm.

(3)Temperature control range of thermal wax actuator is between –20 ~ 230℃.

(4)Lag phenomenon is generally 1 ~ 2℃. Friction of each component part and lag of the component part temperature cause a lag phenomenon. Because there is a difference between up and down curve of traveling distance.

(5)Loading force of thermal wax actuator is difference, it depends on its’ shell size.

Product detail pictures:

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for professional factory provide U-1A00 thermal wax actuator for thermostatic automatic water drain valve Supply to Vietnam, The product will supply to all over the world, such as: Birmingham , Istanbul , Congo , When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we'll be delighted to serve you.

Here I am going to illustrate Toyota Corolla 2004 radiator cooling fan circuit Electrical repair. The cooling fan for this car was not switching on. The complaint was overheating due to stopped cooling fan. Here I am showing step by step repair process instead of jumping to replace the coolant sensor or any other part at once.